The Covid 19 pandemic and Brexit represent a special stress test for supply chains. Whether supply chains in the manufacturing sector pass this test largely depends on a functioning bottleneck management system that balances demand and capacity. Bottlenecks occur when the supply chain or the production systems within a supply chain are unable to adapt quickly enough to an increase in demand. Under current conditions the main reason for imbalances is a lack of personnel and machine capacities, for example because personnel are absent at short notice or because production facilities cannot be used with the usual intensity due to hygiene regulations. In other sectors there is a lack of capacity because demand has risen sharply and cannot be satisfied.

The Covid 19 pandemic and Brexit represent a special stress test for supply chains. Whether supply chains in the manufacturing sector pass this test largely depends on a functioning bottleneck management system that balances demand and capacity. Bottlenecks occur when the supply chain or the production systems within a supply chain are unable to adapt quickly enough to an increase in demand. Under current conditions the main reason for imbalances is a lack of personnel and machine capacities, for example because personnel are absent at short notice or because production facilities cannot be used with the usual intensity due to hygiene regulations. In other sectors there is a lack of capacity because demand has risen sharply and cannot be satisfied.

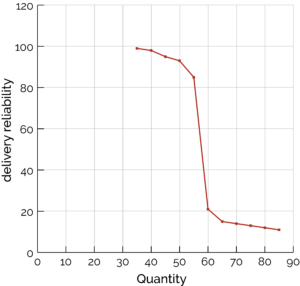

To a limited extent, countermeasures can be taken, for example through extra shifts, overtime and temporary workers. This can increase capacities by 15 to 20 percent. But these measures are for the time being difficult to implement, and when they are exhausted, a domino effect occurs if delivery reliability collapses

Bottlenecks cause a variety of problems

The problems caused by bottlenecks range from a drop in on-time delivery and the build-up of backlogs to higher special freight costs and an increasing proportion of outsourcing, which in turn reduces the company’s own margins. In this situation uncoordinated emergency actions can lead to even higher capacity losses, while a hasty increase in personnel or investment in additional machine capacity will lead to cost increases in the medium term.

The solution: systematic approach, tried and tested methods

ConMoto has developed an immediately applicable, tried and tested modular method for the management and elimination of bottlenecks. It systematically ensures the required outputs to satisfy customer needs. At the first step we establish transparency by evaluating standardized key figures and setting up an efficient reporting system. Production managers are involved throughout the entire process. In daily meetings, we discuss the measures with representatives of all relevant functions and define the necessary target processes on this factual basis.

A key aspect is the holistic view of the value chains. In addition to analyzing in-house production and logistics sites, effective bottleneck management also requires a careful assessment of possible external supply restrictions. This relates to securing material supplies, the availability of necessary service providers and logistics chains. A task force organization, emergency plans and escalation mechanisms have proven effective in safeguarding business operations. This effectively avoids bottlenecks in production and logistics or significantly minimizes them. ConMoto consultants realize fast and pragmatic solutions for bottleneck problems together with customer employees. Stringent project management ensures speedy implementation and effective implementation of measures.

Deutsch

Deutsch