Increase overall plant efficiency with clearly focused improvements

Optimize the value stream with OEE+

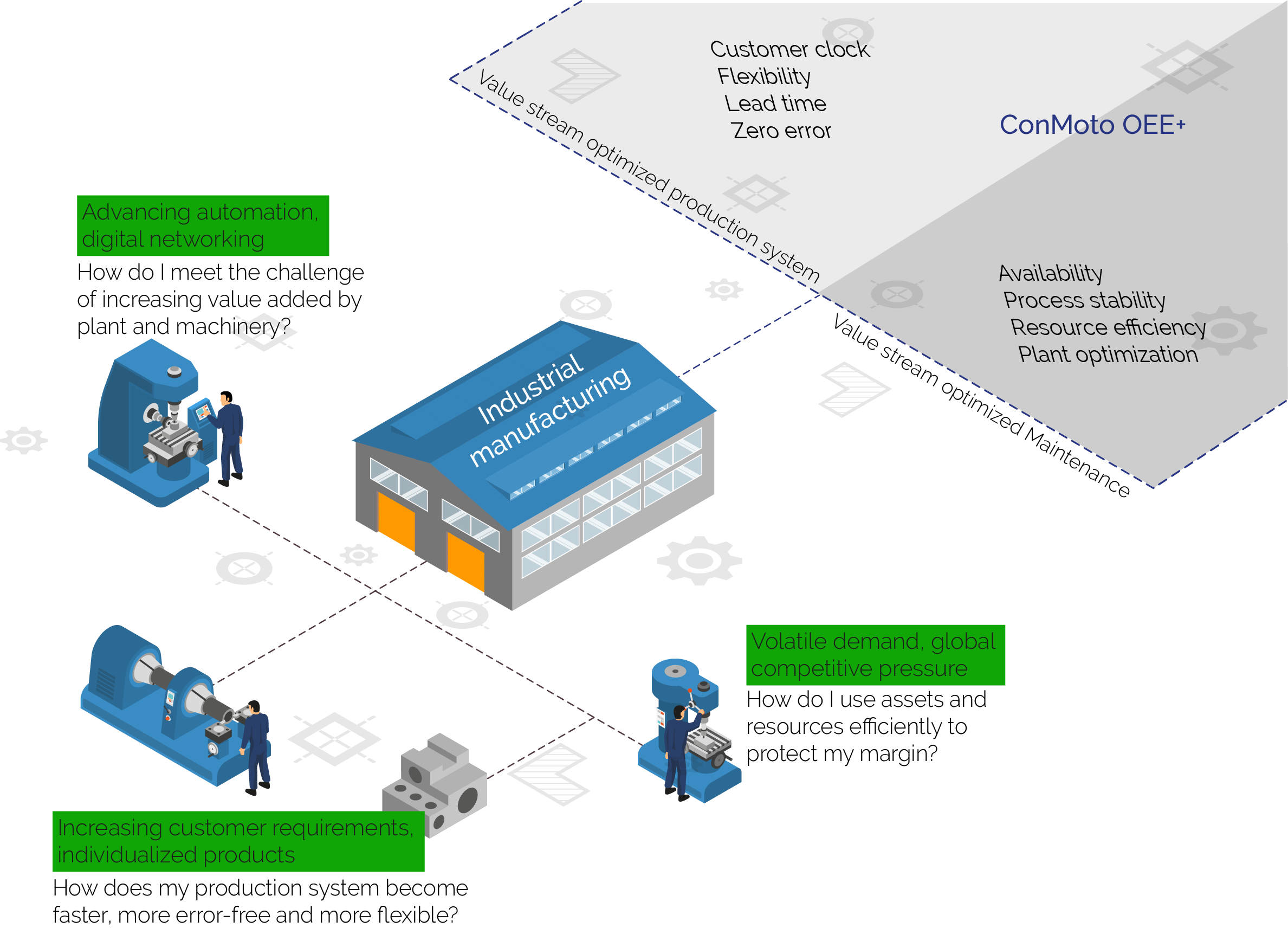

Technological progress is changing factories all the way to the store floor. The demands on production systems are increasing dramatically. Automation and intelligent networking increase the share of value added that plants contribute. With increasing plant intensity, lean organization of industrial production is no longer sufficient. Overall Equipment Effectiveness (OEE) becomes the key performance indicator. The ConMoto OEE+ methodology is an improvement program to realize hidden potential in increasingly equipment-intensive factories. It provides the necessary tools to master new market challenges and exploit opportunities arising from technological progress. The extent to which the path of digitization is followed always depends on cost-benefit aspects. Because even in the age of Industry 4.0, the production system must always be measured against its economic efficiency.

The foundation for a high OEE+ is the permanent optimization of value streams and processes and efficient maintenance.

A value stream optimized production system is based on

- the customer’s takt time as a pacemaker,

- short lead times,

- error-free production and

- high flexibility.

Eine wertorientierte Instandhaltung basiert neben weiteren Zielen auf

- high availability and reliability,

- stable manufacturing processes,

- efficient use of resources and

- continuous plant improvement.

Talk to us.

Every positive business relationship begins with a good conversation. Leave your email address. We are looking forward to get in touch.

The ConMoto OEE+ methodology

The basics of your production system

OEE+ ScoreTest

The OEE+ ScoreTest developed by ConMoto combines the analysis of the production system with a detailed evaluation of the maintenance organization and the overall equipment effectiveness. The test procedure builds on the proven ConMoto maturity models for production and maintenance. Within one week, an interdisciplinary team determines the strengths and weaknesses of the production and maintenance system. The ScoreTest-method evaluates processes, structures and key performance indicators and provides company-specific parameters for improvements that can be quantified using basic data and comparative values.

In addition to “hard” potential, our approach focuses on activating the employees involved. During the intensive workshops, we make clear to production and maintenance employees the complementary goals of both areas. We involve employees and responsible parties as early as the analysis phase. In this way, we achieve a high level of motivation of all those involved, also for the implementation of the jointly decided measures directly following the analysis.

The analysis week at a glance:

- Value stream mapping and design,

- Evaluation of the main processes in production and maintenance,

- Activity structure, ratio analysis and benchmarking,

- Interactive OEE+ scoring and comparison with ideal condition,

- Definition and prioritization of action areas,

- Quantification of potentials,

- Develop an implementation roadmap.

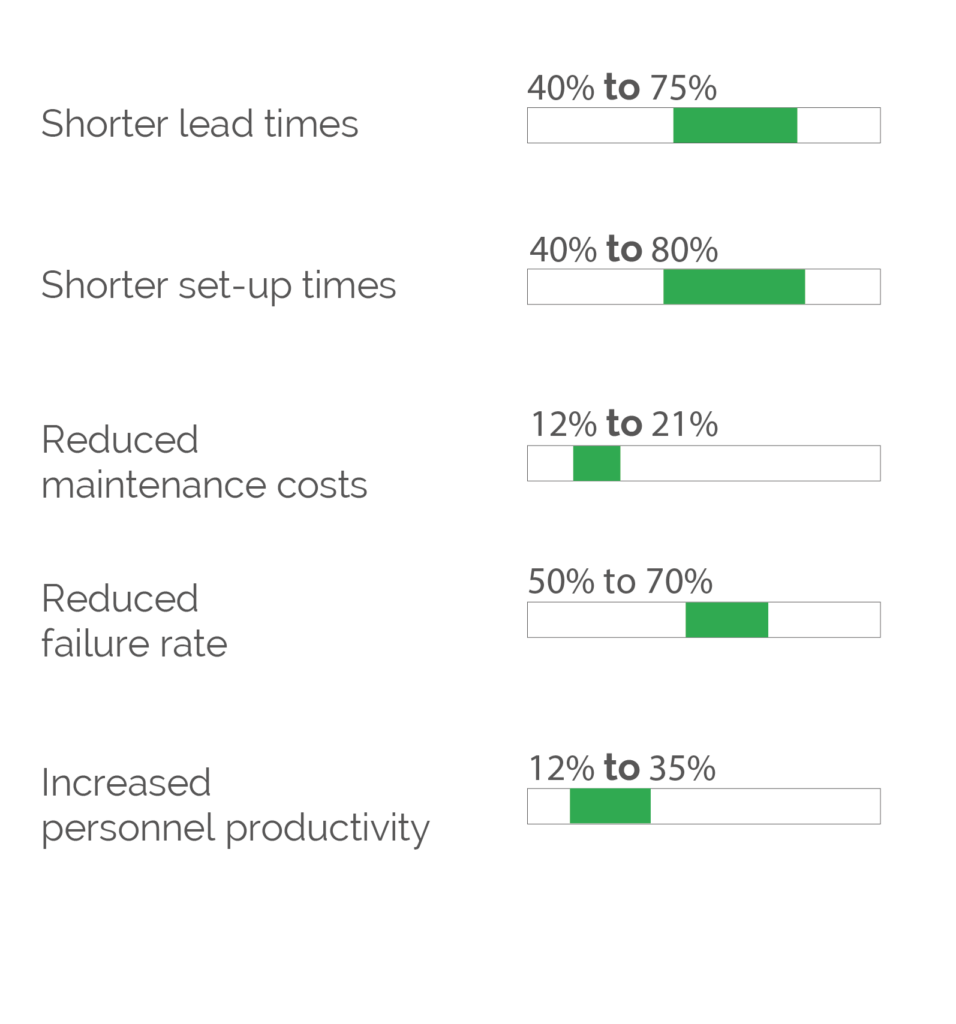

Figure 2: Typical project results for value stream optimized production

Deutsch

Deutsch