Dynamized inventories, maximum security of supply, effective processes

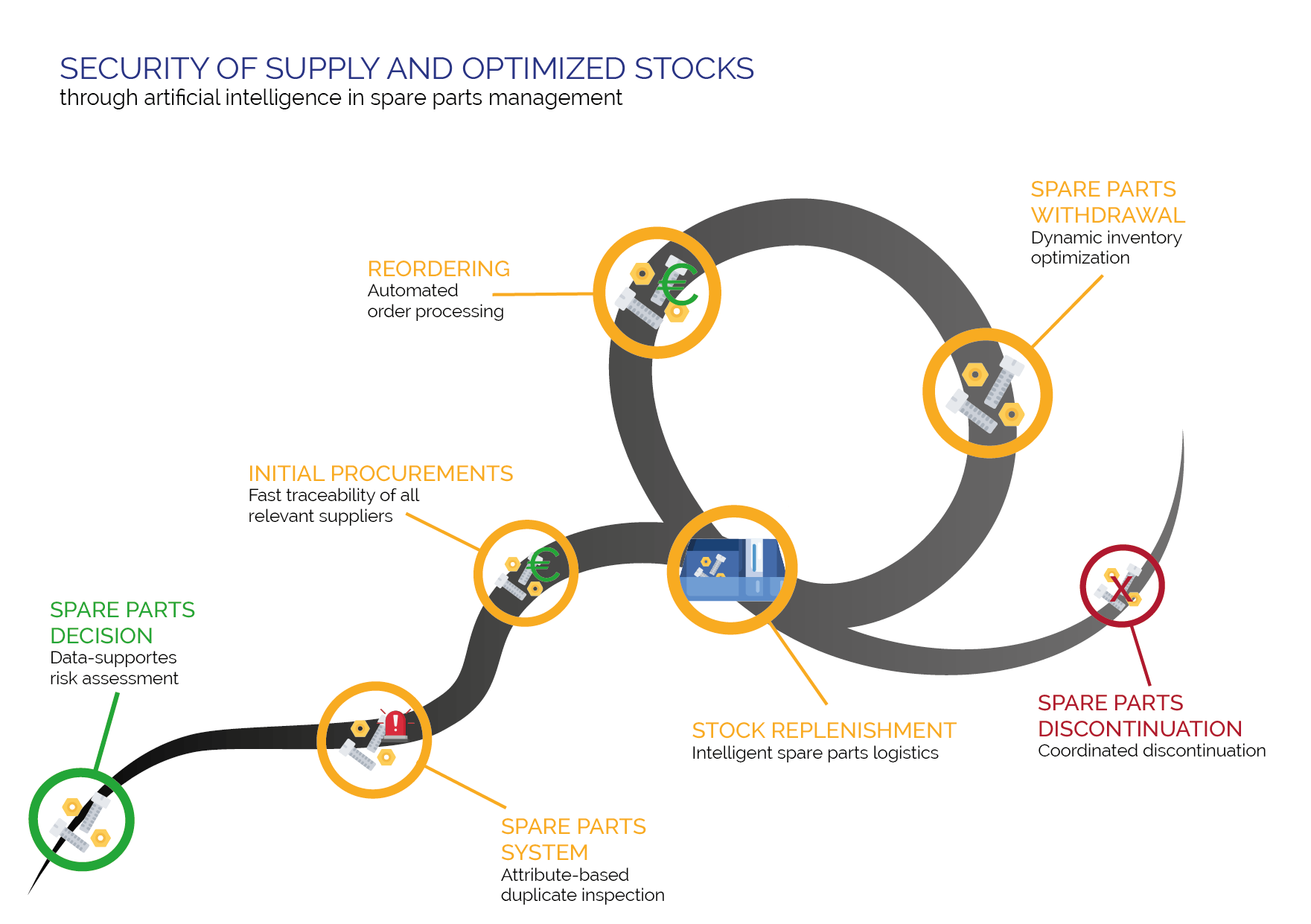

To ensure the effective continuation of production, the availability of spare parts for maintenance is essential. Whether this succeeds depends on many factors: Deciding which spare parts to stock when procuring new equipment, checking whether the parts are already created as items in the parts database, and the number of parts that need to be available at all times. But decisions based on complex factors and a variety of data are also required for procurement, warehousing, and ultimately at the end of the plant’s life cycle. The effort to constantly record, evaluate and contextualize this data generally overwhelms those responsible, leading to suboptimal results: significant over- or understocking of spare parts, associated lack of security of supply and significant costs in the disposition and procurement of spare parts. Better results are achieved by using software that incorporates artificial intelligence and is thus already able to simplify many of the decision-making processes described in spare parts management or to take over routine work completely. ConMoto supports its customers in the planning and application of these programs.

AI supports the development of spare parts strategies and simplifies master data maintenance

The tasks of artificial intelligence in spare parts management already start with plant planning: Do I stock a spare part at all or do I procure it when needed? How great is the risk of a production stoppage? The decision is often based on recommendations from the plant manufacturers, supplemented by empirical data. Here, decisions are already being made today based on empirical data as to whether a part should be stocked. Once the decision has been made, it is necessary to clarify whether the part is already in stock. The identification of an existing part is not always possible immediately, since parts are designated inconsistently or master data is missing. Whether parts are identical can therefore only be determined by matching physical characteristics. If these characteristics are not created in the warehouse system, the AI-assisted search via the unified nomenclature helps, such as e-class systems with web-based solutions. Today algorithms are already used to identify spare parts based on material characteristics, with the aim of avoiding multiple stockpiling of duplicates.

AI goes one step further and independently determines master data through web crawlers. Who is the manufacturer of the original parts? Is the spare part substitutable? Are there any indications of component weaknesses? KI independently maintains and supplements the technical master data based on attributes, performance parameters and other material characteristics. It can also propose the substitution and standardization of the spare parts that are economically most suitable for the company.

AI dynamically calculates spare parts inventories for economically optimal availability

The capital tied up and the stockpiling expenses compete with the production losses, which can become very high very quickly if the part is not available in time. The AI system in spare parts management determines the optimum safety stock for this purpose. To this end AI compares the frequency and impact of failures of comparable components and correlates them with potential inventory and procurement costs, which in turn consider component costs and replenishment times. Consequently, an economic optimum is calculated, which is constantly adjusted and defines the dynamic safety stock.

The fact that a spare part is no longer available from the supplier often only becomes known when the part is needed. In extreme cases, the supplier has already filed for bankruptcy and can no longer be reached. In this situation web crawlers can take over the matching of the company’s own spare parts inventories with the information on the web. Planned decommissioning of equipment also requires a run out of a spare part. AI calculates the risks of the remaining operating time. In this way, inventories can be reduced in time to avoid overstocks in the end. If the spare parts are still needed in other plants or factories, AI can support an update of optimal storage locations and inventory levels.

AI handles spare parts procurement with suppliers across companies

In addition, the procurement of spare parts is also optimized by AI. Component age, load situation and durability are the input variables that make it possible to dynamize the safety stock, which is fixed number today. Predictive and prescriptive maintenance solutions are closely linked to optimal scheduling parameters through algorithms. A dispatcher should be relieved of routine tasks and only decide on the provision of parts from the warehouse in selected cases. For order parts, procurement is more complex. But even in this case, operational tasks such as ordering and issuing the delivery bill and invoice can be clarified between the AIs of the ordering party and the supplier. Chatbots handle everything from supplier support to confirming delivery dates.

A web crawler can also clarify whether there could be disruptions and thus delayed delivery and update the delivery date accordingly. The sources of information range from social networks and online media to the information systems of port operators and customs authorities or weather databases and earthquake observatories.

Similarly, AI works on platforms that examine online sources of information or details from customers and suppliers to determine which suppliers around the world are best suited to manufacture or supply specified parts or components. Among thousands of suppliers, the programs quickly find the companies that can fulfill an order the fastest and cheapest with the best possible quality. This makes it possible to speed up the pre-selection of suppliers or quickly find an alternative source of supply in the event of supply chain disruptions. AI provides the information; the decision is made by the buyer.

Before buyers can automate strategic and operational processes with AI, they need to get their master data in order and create central supplier records that contain all supplier-related details from contracts, purchase orders and invoices. SAP is currently developing an AI-based chatbot that reviews contracts and makes suggestions for improvements based on historical patterns. For example, the chatbot can suggest different payment terms or recommend a specific contract clause that complies with the insurance regulations of a particular region.

AI generates synergy effects in spare parts logistics by centralizing strategic spare parts

In addition to simplifying purchasing processes, supporting scheduling and dynamizing inventories, availability and security of supply are particularly important for maintenance. But not every part has to be in your own on-site warehouse to ensure effective maintenance. Consignment, vendor managed inventory, a contractually agreed minimum inventory with the manufacturer or distributor are to be evaluated economically depending on the delivery time. Especially for large, expensive spare parts that are difficult to replace, a central storage location may be sufficient for several production sites of a company. Considering all necessary input parameters for the decision is hardly possible with simple on-board means. The AI can simulate the optimal supply routes and locations of availability depending on the demand probabilities and required transportation times. Whether from the external or internal storage location to the plant where the spare part is needed, the maintenance engineer can be relieved of many of his current tasks – from determining stock quantities to inventory management to the route to the warehouse.

Companies must create the conditions for AI in spare parts management today

The examples show the value that AI generates in maintenance. Process boundaries are dissolved; data is the fuel of the system, regardless of the process. Added value comes from linking specialized AI systems: for example, linking Prescriptive Maintenance with Intelligent Spare Parts Stocking to create an integrated AI solution. ConMoto supports you in describing the requirements for designing AI systems in maintenance and spare parts management. Together with you, we develop the future-oriented use of AI systems in spare parts management and thus ensure your sustainable business success.

Deutsch

Deutsch