Technological change, intensified competition, and ever shorter product life cycles as well as rapidly changing market conditions lead to shorter-lived product strategies, which in turn have a direct impact on production strategies, the production footprint and plant development planning of companies. An important goal of mid- and long-term footprint strategy adaptation is to downscale production and sales of perspective discontinued products as profitably as possible and to ensure the necessary flexibility to adapt to changing market conditions. ConMoto has developed a structured approach that defines suitable transformation scenarios for production sites and products.

These scenarios are based on a clustering of phase-out strategies that act as a basis for the design of the Production Footprint:

- Last Man Standing: declining demand leading to consolidation opportunities and strong cost orientation;

- Harvest: traditional, shrinking market with constant profitability and service & competitive environment;

- Reprioritization/Sunset: products where demand is not expected to increase in the future (sunset market).

The Last Man Standing (LMS) strategy path is particularly challenging and requires consistent transformation of entire business units because it is foreseeable that demand for these products will decline sharply in the future and disappear in the medium to long term. This leads to a pronounced cost orientation and strong focus on competitiveness and cost leadership. The goal of LMS strategies is to be among the top 3 in terms of costs in the market environment and to address the demand of existing, but also new customers.

Cost leadership by shaping the production footprint

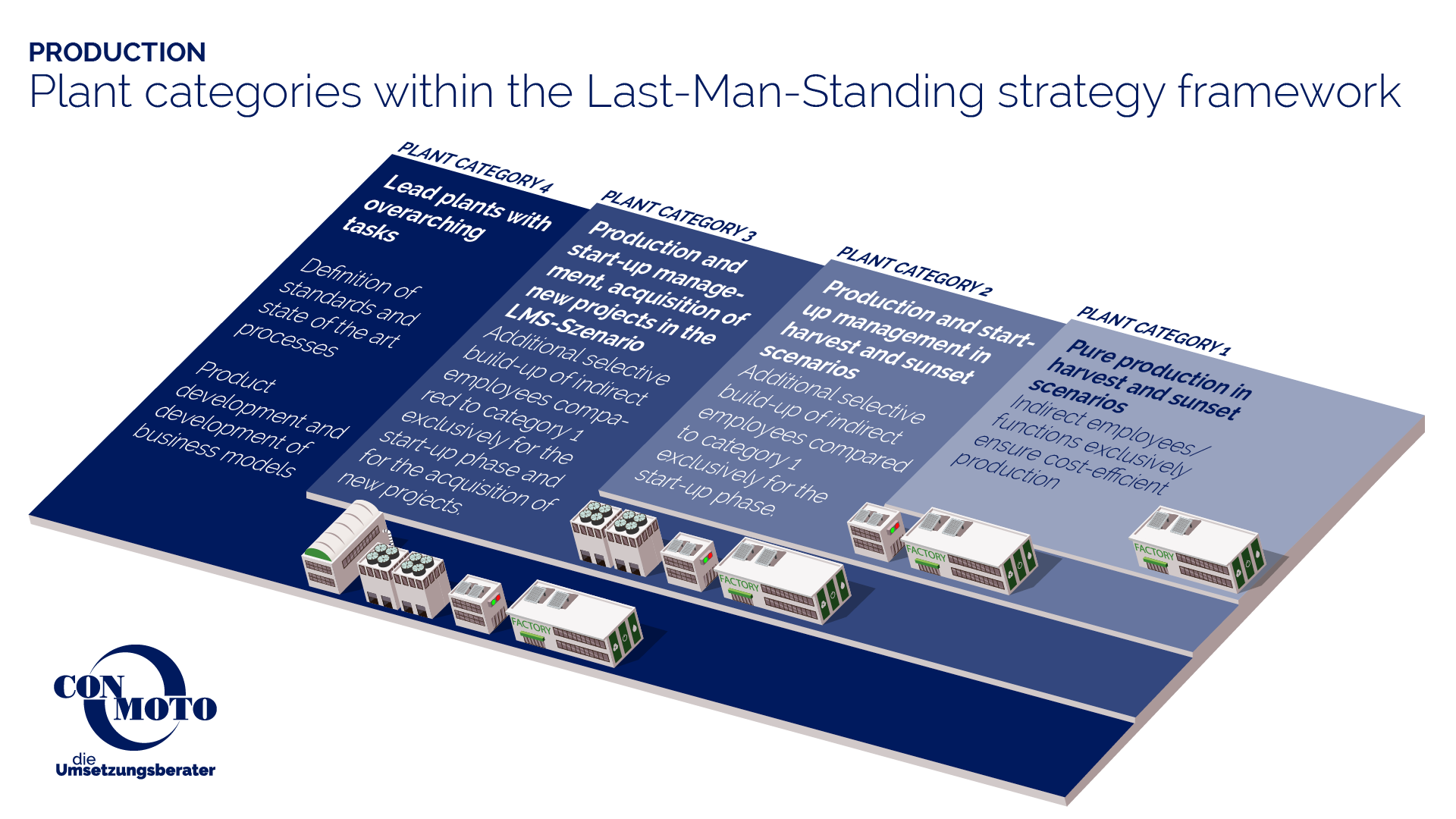

To become a cost leader, the Sales and Operations functions in the company must work closely together and run through various market and price scenarios to adjust the production strategy on this basis. The implementation of an adequate strategy stands and falls with the design of the production footprint. ConMoto has defined three different plant categories in customer projects for LMS harvest-sunset strategies:

Plant categories in the context of the last-man-standing strategy

Category 1: Pure production in harvest and sunset scenarios.

Clear focus on a cost-efficient production process.

Exclusively to ensure cost-efficient production, there are employees/functions in the indirect area.

Category 2: Production and start-up management in LMS, harvest and sunset scenarios

Selective build-up of indirect staff beyond category 1 exclusively for start-up phase management.

Category 3: Pure LMS scenario

Additional selective build-up of indirect employees for the management of the start-up phase and for the acquisition of new projects.

A fourth, higher-level category is represented by plants that assume a leadership role (lead plant concept) in the corporate value network. They have overarching tasks such as defining standards and state-of-the-art processes. They support the other plant categories with indirect functions as required. Among other tasks, they take the lead in developing new, innovative products and business models with high profitability.

Transformation to the optimum production footprint

The adaptation of the product and production strategy is implemented via the optimal production footprint. In the first step, the existing plant structure is analyzed and then the appropriate target footprint is designed according to the LMS harvest-sunset scenario. Target states are defined for

- the role of a plant in the production network (categorization),

- the value-added depth of the individual plants

- the resource endowment and

- the personnel structure per plant.

An optimized production footprint increases the profitability of products even in late phases of the product life cycle. This frees up resources for investment in growth projects. This creates opportunities to increase the market share of products even in LMS, harvest or sunset scenarios. At the same time, the necessary flexibility of the production network must be ensured to prevail against the competition despite the changing market situation.

ConMoto has the project experience and benchmark knowledge to align the product portfolio, the production strategy and the production footprint: Not only for your company’s cost leadership and profitability, but also to sustainably implement your strategic goals.

Deutsch

Deutsch