Situation

Our customer is a German First-Tier-supplier for the automotive industry. The company sources important parts from a supplier in Ukraine. However, the supplier’s delivery reliability is low. Agreed on improvements have so far been implemented only slowly and inadequately by the supplier. Consequently, a backlog of 30 days has been building up and the trust in between the two companies has decreased. With a team of three consultants ConMoto spent four weeks at the Ukrainian supplier’s site. In essence the aim was to create transparency, define concrete measures to reduce backlogs and start implementation.

Results

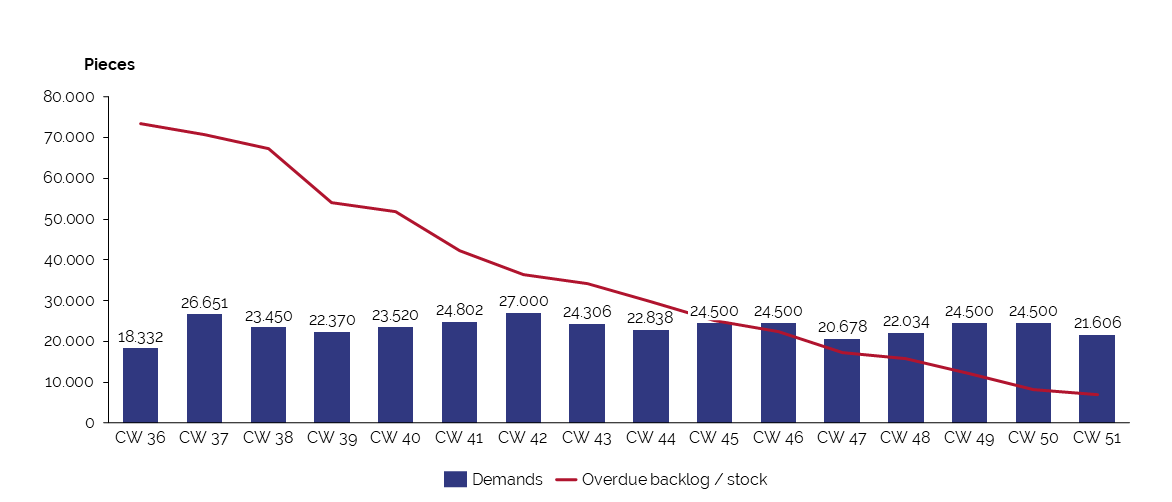

ConMoto’s on-site team in the Ukraine succeeded in creating transparency about planned deliveries and daily production output. Daily reporting on the delivery situation and range coverage helped to create new trust in communication. Clearly defined project measures and the introduction of essential elements of shop floor management such as e.g. an hourly count increased output. This led to a sustained reduction in the backlog of deliveries.

Deutsch

Deutsch